Turbo

TOWARDS TURBINE BLADE PRODUCTION WITH ZERO WASTE

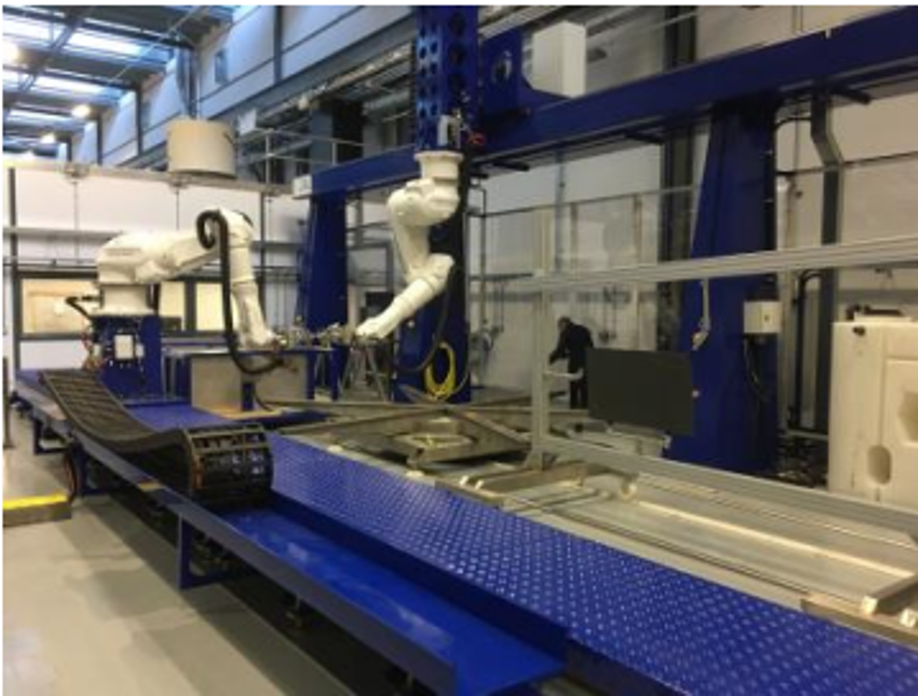

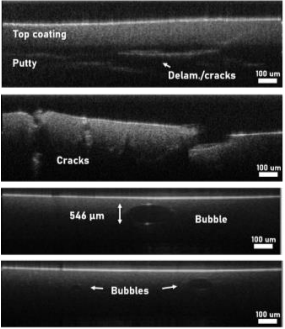

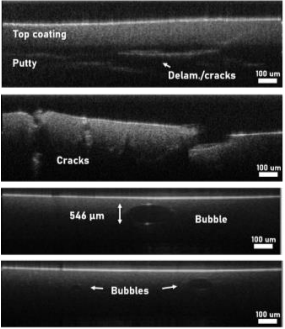

Wind turbines are already part of everyday European life and are an essential part of the strategy to meet the Green Deal targets. Almost 3500 turbines (>10000 blades) were installed in 2019 alone. Wind turbine blade (WTB) size is rapidly increasing with new offshore blades >100 m in length. Yet remarkably, the technologies used to manufacture blades have not changed significantly since the late 1970s. Composite blades are manufactured using resin infusion and coating processes which are prone to defects resulting in high rates of re-work, scrap and repair.

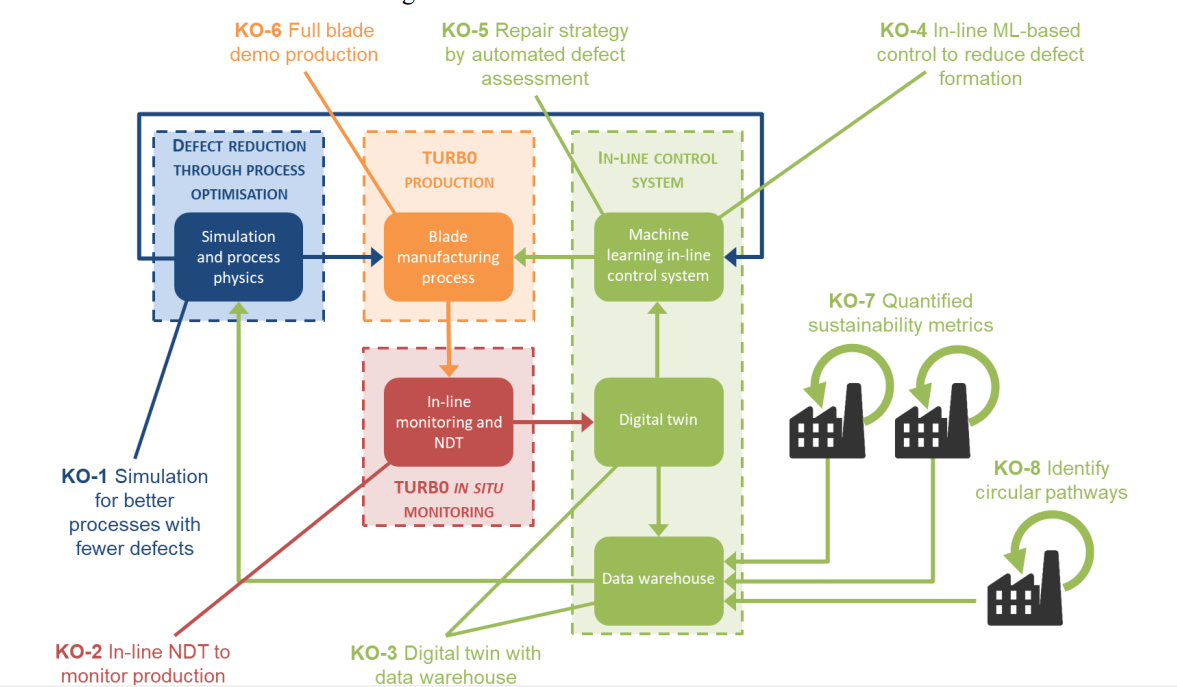

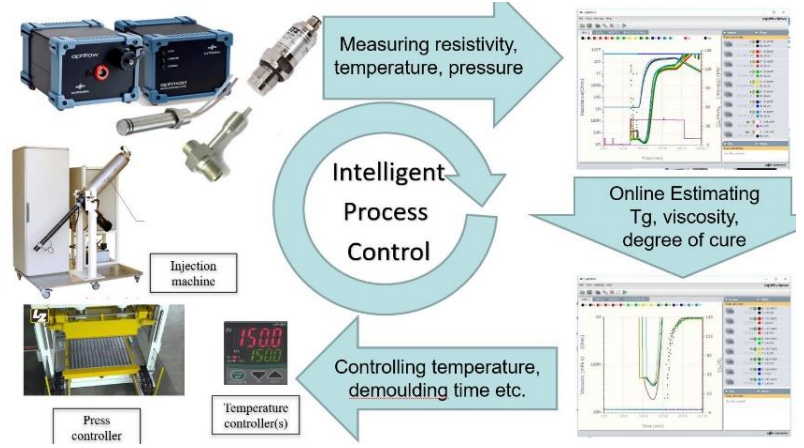

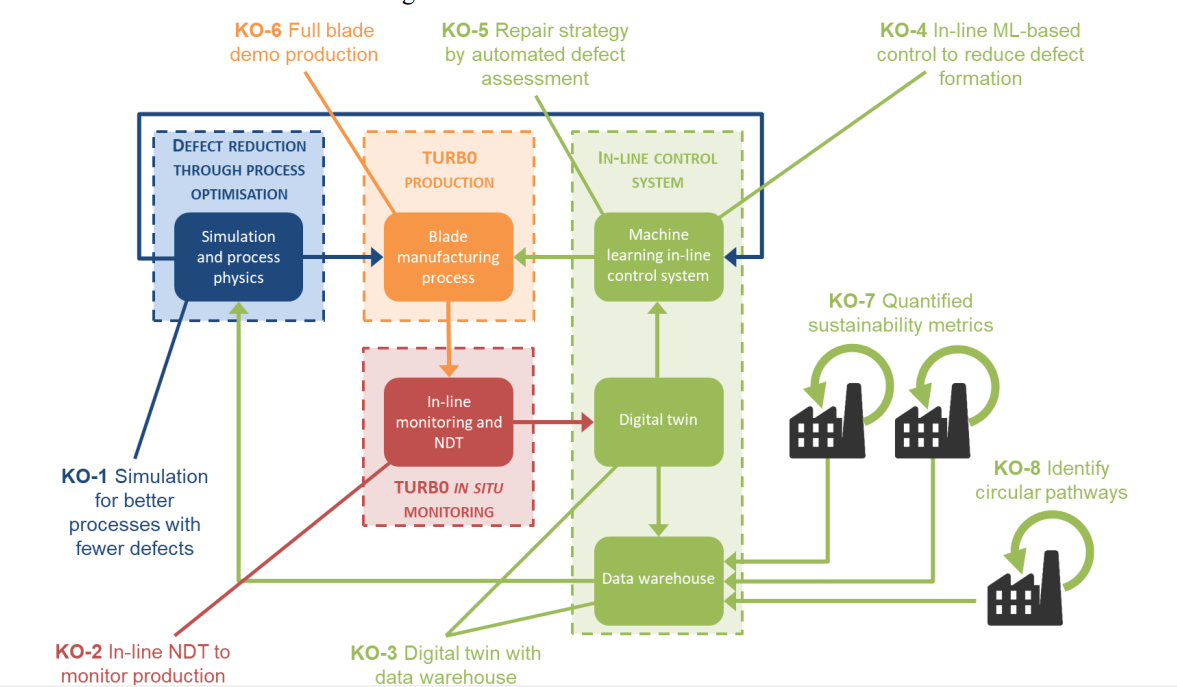

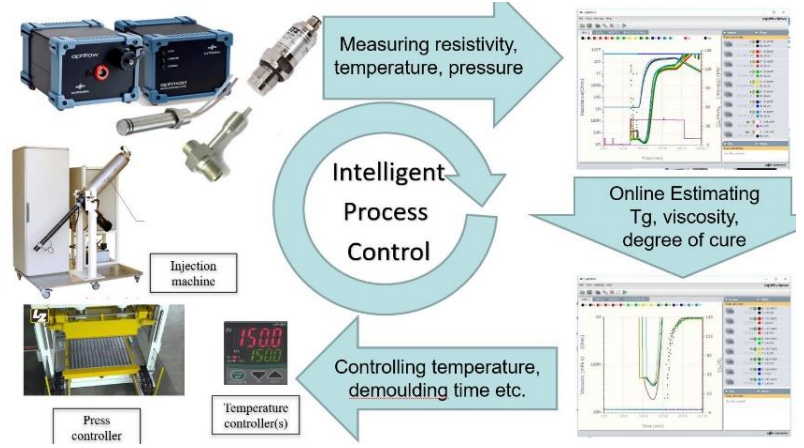

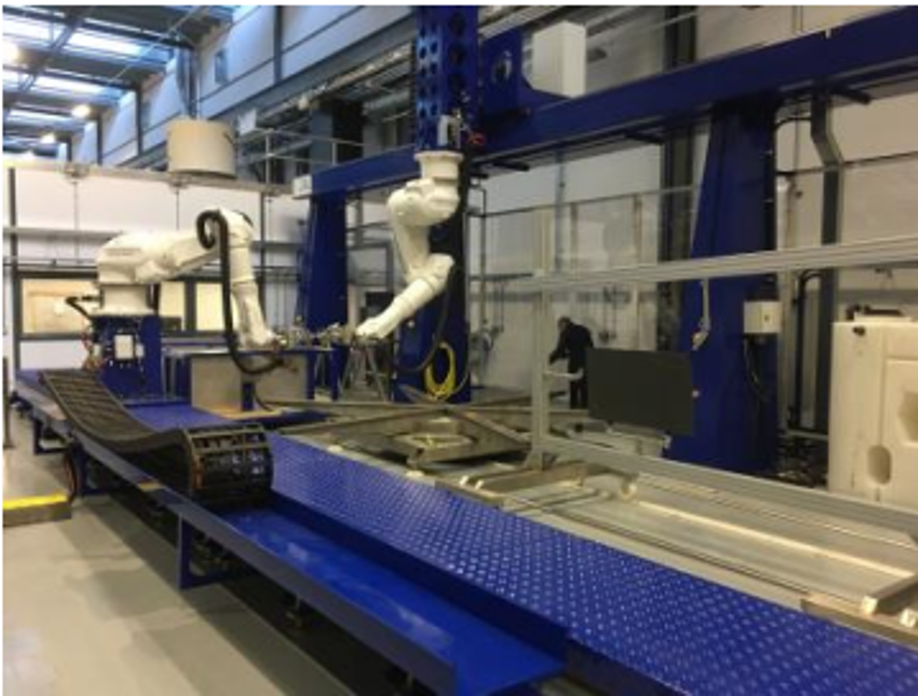

To meet the worldwide demand for sustainable green energy, the wind industry must transform itself to be more resource-efficient. To enable zero-defect and zero-waste manufacturing, the industry needs game-changing, innovative, disruptive and ambitious ideas to produce new manufacturing methods. Recent advances and developments in Industry 4.0 present an opportunity for the wind industry to transform. Enabling data-driven manufacturing decisions to reduce defect formation and improve defect assessment will drive the scrap rate down as well as optimising the manufacturing processes to decrease production waste. TURB0 will bring these developments

together in a coordinated workplan to develop new methodologies towards zero-waste WTB manufacturing. The core of turbo will be the development of machine learning-based algorithms for in-line process control during turbine blade production.

Partners